The influence of modern technology has a real impact on the mobilization of national developments, one of them is trying to innovate by applying 3D printing technology in the automotive industry as a limited mass production. In addition, the volatile dynamics of some market places demanding a new valuable and even unique products. Especially in the market place of motorbike customization. However, efficiency becomes one of the problems along the production processes of custom motorbike, which can be done for a long period of time.

Therefore, there is another chance to improve this problem by helping them with modern technology such as 3D printing. This tool can be applicable not only solving this issue, but also improving the digitalization of 3D print manufacturing in Indonesia. But there is another problem comes with the limited dimensional printing area. So, approaching solution comes with designing modular body parts, in order to improve the efficiency of conventional technology production processes for custom motorbike workshop.

With those backgrounds, I proposed my final project in 2021 to design modular motorcycle body parts with fused modeling system (FDM).

DEVELOPMENT

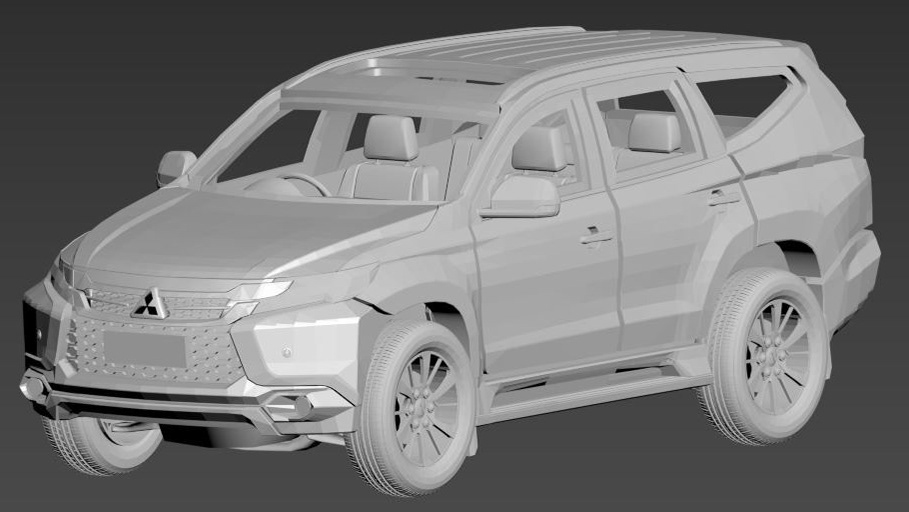

In design development, I prepared the bike model data and also the dimensions in the beginning of time in order to measure the details of the motorbike, because it took a lot of time. So, I reversed the designing process steps to make sure this project can be done on the due date. The measurement tools that were using such as : digital caliper, mistar, 3D scanner photo by Zephyr, 3D Modeling programs which are 3Ds max and Rhinoceros. From 3D scanned model, I was using parametric modeling method to build and refine surfaces by using 3Ds max and rhinoceros modeling programs based on the actual dimensions that have been measured as guidances to make some sketches.

All of the sketches were inspired by the sturdy structure of the bridge with many different styles, starting from first sketch to the final sketch. Based on second observation and market survey, design number two of the second design and the third pattern module were chosen as the highest percentage. The tangible result of this project was only the front end of the motorbike.

The objectives of the body part design were to give an aggressive, strong, and unique impression by showing the inner structure of the motorbike. On the other hand, to improve efficiency related to material waste and decreased printing time with the structure design. This modular design consisted of three module classifications such as : pattern module, adaptor module, and supporting module.

PRODUCT

3D PRINTING PRODUCTION DATA

CONFORMANCE TEST

Looseness Vibration Test